lightpainting © Jo Torres, for the Isness VR project 2020

eTextile data gloves - touching the digital

We live in a world of accelerating digitisation, where our physical senses are inevitably mediated by software. While algorithmic intermediaries are essential to computational design logic, these opaque black box systems are naturally designed for optimisation, rather than open-ended questions…

And from the perspective of human experience, ‘touching’ intangible digital worlds is still an inherently physical, tangible act. Luckily we get to design reality. Layers of human augmentation can be designed from the inside out, rather than externally imposed on the conscious mind as an extra data layer to digest, and interpret… else the technology is wearing you.

In this design space, human-centric opportunities for curiosity and play are essential, and our access points should be understandable, hackable and participatory. These eTextile data gloves are an evolving, explorative contribution to how we can touch digital worlds.

Glovers report a more intuitive experience compared to say, the glitches experienced in VR camera tracking, or the encumbrance of handheld controllers. Instead of an additional barrier to access, we can use instinctive movements to experience ourselves as part of a system.

A consistent anecdotal finding comes each time a new digital solution [or replacement] is introduced: data gloves have a moment of obsolescence… before making an inevitable and winking return. They usually re-emerge as a tool for human-centric problem solving, to explore new limitations presented by the current digital ‘successor’. So why do we still need a complex physical object when it can “just be done with cameras”? Besides the obvious benefits for commercialisation, this is still an open question. And that is exactly the kind of question these gloves - these tools - can be used for. [NB also to look cool].

Tried and tested human design and the familiarity of clothing as a ‘second skin’ can be grounding in a dizzying world of data. The MiMU Gloves are a perfect example. They give us empirical human control points in liminal digital space. It’s not one or the other. Experimenting with how and where the tangible meets the digital instead broadens the canvas of exploration. MiMU [formerly theglovesproject.com] has existed over a decade and is still going strong because the MiMU Gloves are a tool for creation.

Projects below are arranged chronologically: newest first. The documentation is focused on the concept design, e/textiles and hard/soft connections. The textile explorations form a developmental chronology, and each case study is unique in how it is applied via microcontrollers, software and network systems.

[Watch this space] for a long overdue photo/info dump and tutorial of archival - and still relevant - eTextile fabrication techniques.

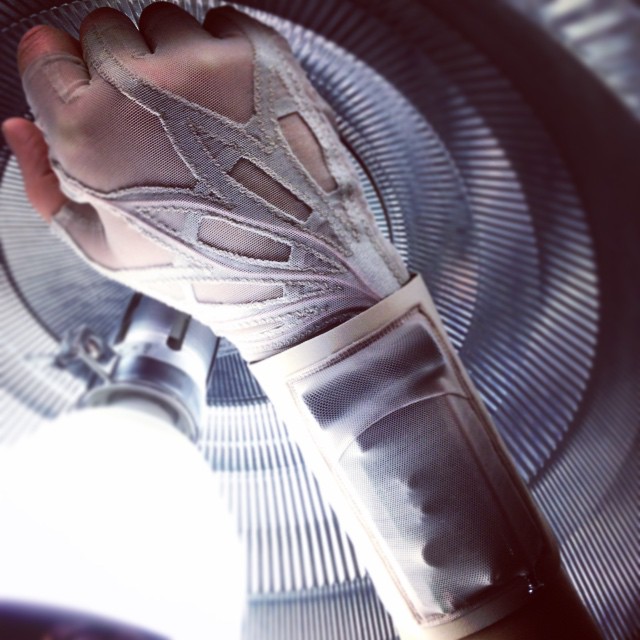

‘TENDONS‘ - a biofeedback glove for music performance [2023-24]

TEI PAPER - RaveNET: Connecting People and Exploring Liminal Space through Wearable Networks in Music Performance | TEI PERFORMANCE - Liminal Space: A Performance with RaveNET

This glove is part of a project called raveNET, a modular network which connects people to music, enabling musicians to modulate sound using signals produced by their own bodies or the bodies of others. TENDONS is an evolving half-glove/wraparound strap, measuring galvanic skin response, pulse, and movement of the hand. For raveNET, these signals are filtered, normalized, and amplified to control voltage levels to modulate sound. Together, musicians and nodes form RaveNET and engage with shared liminal experiences.

Designed to facilitate questions and reflections on collaborative creative processes, spaces between bodies, human presence and control within a digital network, and how this makes us adapt our movements in response to these augmentations.

BELOW [L-R]:

1 - 6: performance prototype with closeups of textile adaptations for commercial sensors [buttons x3, pulse oximeter, GSR electrodes, IMU]

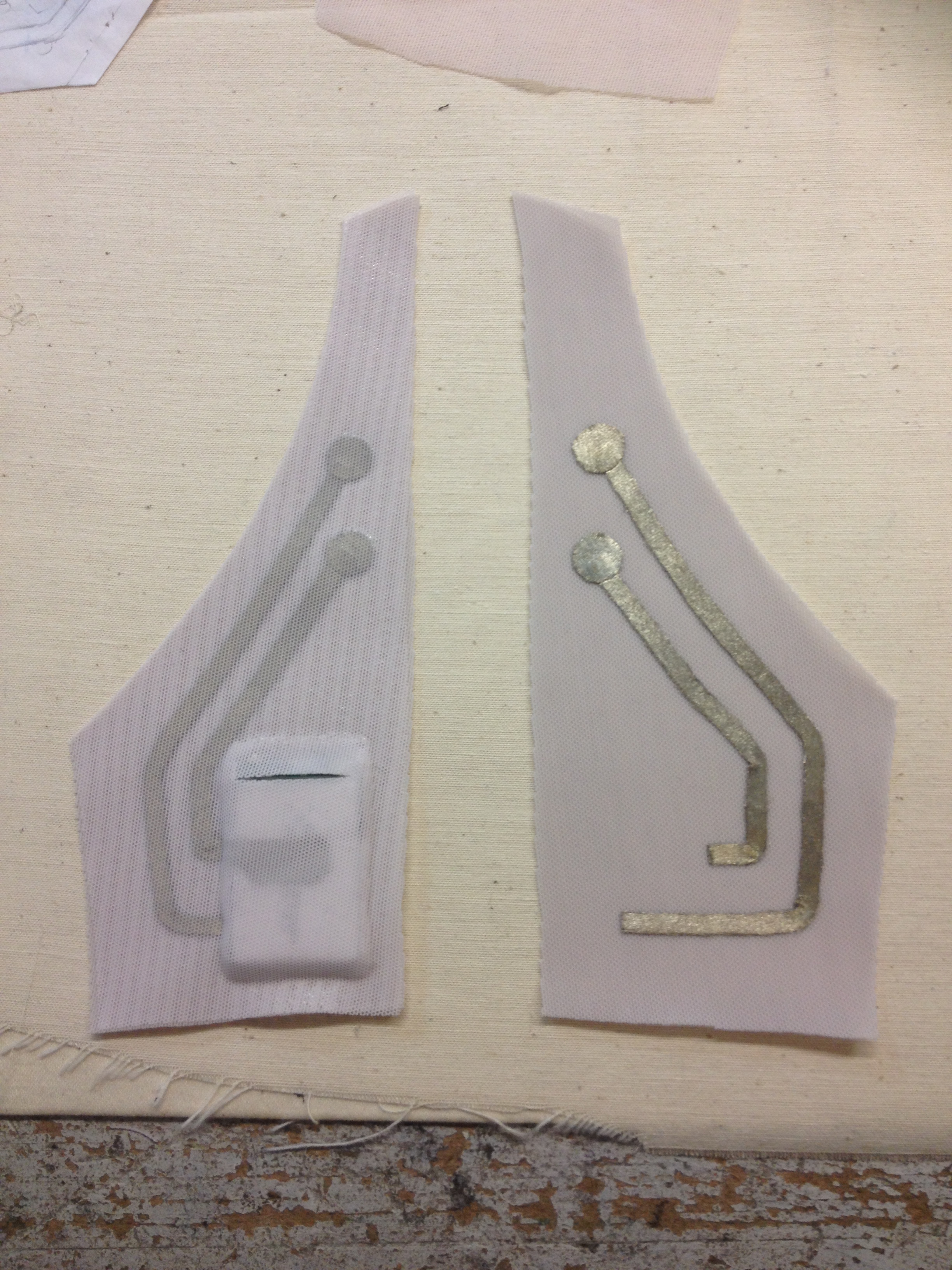

7: toile [testing the pattern] - circuitry is visible for fitting and design refinement

8: first raveNET jam session with TENDONS, BONES [a breathing corset] and VEINS [a cap which reads EMG] - all have an IMU and connect [bass, vocals and beats, respectively] to the central network

9: Paul breaks his hand and can’t wear the glove! Testing how we can adapt the design for the inaugural TEI performance, while he is healing

10 - 12: updated form factor - ripping out the tendons and reverting to a wraparound strap to fit over a hand cast

A initial design, a stretchy wrapped cuff which tensions sensors to the hand | B initial one-piece prototype | C a more traditional glove pattern, to stabilise sensors and reduce bulk | D updated prototype design | E performance prototype with aesthetic detailing

HYBRID MUDRA GLOVES for HTC Vive/Valve Index + Meta Quest [2022-23]

TUTORIAL | TUTORIAL/WORK-IN-PROGRESS IMAGES | JONATHAN’S ‘PINCH GLOVE’ PROTOTYPE

A re-imagining of the MUDRA gloves [below], this design adds compatibility with Meta’s cheaper, more accessible [and yucky] Quest headsets. These HYBRID gloves incorporate a PINCH glove prototype [tutorial link above right] so the gloves can be connected to either the Vive Puck or integrated into Quest hand tracking via a TinyPico microcontroller. The hardware can easily be switched between the two systems. The gloves are now grey - a specific tone chosen for how Quest recognises skin colour - to maximise camera visibility for hybrid hand tracking.

The glove adds an unambiguous electric contact to the Quest system, rather than relying on headset camera detection in hand tracking. This means the gloves work when your hands go out of range of the cameras. Earlier Mudra gloves relied on external HTC Vive lighthouses, so the addition of the TinyPico circuit facilitates more free range use. The design accounts for the retrofitting of existing Mudra gloves, rather than remaking the more laborious textile part. The circuit has two sets of wires, so if one fails the other remains useable, as well as keeping the electronics simpler: the DIY friendly approach removes the need for the two circuits to overlap electrically or require an additional custom breakout board.

Additional feature: A button mounted on the index finger to facilitate more navigation options and/or state changes. All inputs are simple [on|off] switches, recognisable in software as a game controller.

BELOW: PINCH glove [black] and HYBRID glove [grey] | FIGURE BELOW RIGHT: evolution of the MUDRA gloves

‘MUDRA’ GLOVES V.3 - design longevity, repairability and use ‘in the wild’ [2021]

UPDATED TUTORIAL [JUMP TO SECTION 11] | GLOVES IN THE WILD - ISNESS D - NATURE SCIENTIFIC REPORTS

Etextiles can be an amazing way to quickly fabricate circuits but there are design tradeoffs to consider. Minimal manipulation of materials can preserve textile characteristics of softness, comfort and pliability, but exposed conductive circuitry can more rapidly deteriorate via factors such as mechanical friction, sweat and oxidisation. The MUDRA V.2 gloves were used for 50+ hours in ISNESS, and reviewed and repaired after the study. The gloves suffered a critical increase in electrical resistance along the eTextile traces and at the fingertips, making the connections unstable [see image/click for video below right]

The V.3 design update removes the longer textile traces on the fingers, replacing them with wires to increase longevity while maintaining primary design features: softness and comfort. The hard/soft connection to the wired circuit [a soldered and stitched wire loop] moves from the back of the hand to the back of the fingertip, the extended wires now encased between two super-fine layers of fabric, and can be seen snaking along on the back of the fingers. Extra length is added for strain relief but the soft silicone wiring is imperceptible to the wearer.

This more robust design was sent around the world and used in a citizen science study of a remote VR experience called ISNESS-D, where participants dialled into a shared virtual space to experience a guided ritual which elicited novel experiences comparable to psychedelics.

SUSTAINABILITY - Besides design-for-repairability, MUDRA gloves benefit from sustainable materials research done for MI.MU Gloves production design. Petrolium-based neoprene [originally designed to line landfill and last 1000yrs, FYI] is replaced by YULEX FOAM a natural rubber alternative, and technical knit ‘lycra’ fabrics are from CARVICO’s 100% recycled range. Sustainable design is a trajectory. These high performance technical materials are as good - if not better- than their predecessors. NO EXCUSES

MUDRA glove repair/maintenance [CLICK FOR VIDEO]: after 50+ hours use, resistance in the eTextile circuit increased due to oxidisation and friction damage to the conductive fabric. All gloves displayed similar readings, based on hours used. An embroidered copper thread was added: chain stitch along traces and running stitch at fingertips. The V.3 update replaces the conductive traces, prolonging the lifespan of the gloves. LEFT: after repair 10-26Ω. RIGHT: before repair 80-130Ω. [also: HOW PRETTY IS THIS?!]

‘MUDRA’ GLOVES V.1 + V.2 for Isness and Narupa, aka OMG-VR - designed for the HTC Vive Puck and lighthouse system [2019-2021]

TUTORIAL | WORK-IN-PROGRESS CONSTRUCTION IMAGES | 2019 OMG-VR PAPER ON ARXIV | ISNESS PAPER - GLOVES IN A 2020 PSYCHEDELIC-ADJACENT VR STUDY

MUDRA gloves began as an investigation of strategies to move beyond controller-based interaction in VR. The gloves enabled research scientists to use their hands and proprioceptive senses to manipulate complex 3D simulations of molecules in a powerful physics engine called Narupa.

Inspired by the HYBRID V.1 gloves [below] the ‘MUDRA’ gloves were initially prototyped, via published tutorials, by a member of the IRL lab in Bristol University. [see: V.1 in Mudra Glovolution figure above] The simplified design is actually closer to the continuity tester glove at the bottom of the page: losing the bend sensors and utilising the simple fingertip on|off switch by pinching together conductive fabric at finger and thumb in a ‘mudra’ pose. The Vive Puck is mounted on the back of the hand so the gloves can communicate with ‘lighthouse’ bases and be seen in VR.

Open-source Mudra Gloves for VR (OMG-VR) V.2 were workshopped with the IRL, refined for boutique production, and used in a collaborative research project called ISNESS. This project uses molecular simulation in a specially designed instance of Narupa to create a VR ‘ritual’, which was then tested for it’s comparable effects to psychedelics. The study won best paper at CHI2020 and inspired development of a remote version of the ritual [ISNESS-D] during the Covid-19 pandemic.

Despite their technical [electrical] simplicity, the in-world effect of the textile form factor produced notable positive feedback. Users reported being able to ‘feel’ molecules. Besides the psychophysics aspect, it remains unclear if this was also due to a small delay within the software visuals and/or fluctuations in the electrical connection of the switch. Either way, the physicality of the gloves positively augmented VR experiences, facilitating novel opportunities for co-located VR interactions such as holding hands, rolling on the floor [kind of a thing before hand tracking arrived] and ‘touching molecules’.

HYBRID GLOVES - sci-fi imitates science imitates sci-fi ∞ [2018]

A design refinement of the etextile bend sensor gloves below, these ‘hybrid’ gloves were a design experiment, actually commissioned for a futuristic Yamaha commercial! It is part of series by inspired director Diego Indraccolo [who in a past life was an incredible fashion photographer].

Inspired by Diego’s design brief, a new feature was added: the touch pad fingertips are an extension of the conductive traces used to connect the bend sensors. This feature was obvs not utilised in real time in the commercial - besides the Minority Report visuals - but it did actually function, and went on to inspire the commission of the next iteration of the gloves for some serious science!

This design reconfigured the connections of the custom PCB seen in the previous iteration, meaning the glove could be easily un/plugged, and had the beginnings of a structural mount to add things like wifi in the future.

FULLY TEXTILE BEND SENSOR GLOVE with custom eTextile breakout board [2017]

TUTORIAL [watch this space] | WORK-IN-PROGRESS IMAGES

Putting earlier design explorations to the test, this design was workshopped at Autodesk’s Pier 9 by two accomplished technologists who had very little experience with fabrics. Shalom Ormsby and Artyom Maxim constructed etextile gloves, using the patterns and instructions developed to propagate the DIY designs.

This glove itself is all textile, with all wiring and soldering replaced by conductive fabrics. The whole circuit is bonded with stretch adhesive film, using a domestic iron and no stitching. Minimal sewing and stitching is applied only in the fabrication of the glove itself: two seams, one to connect the glove upper and palm, the second to attach the glove to the cuff.

The textile circuit connects to a custom breakout board via miniature textile snap fasteners, which bite through the fabric and conductive traces to connect the circuit to the PCB. The flat ‘female’ half of the snaps on the glove connect to the protruding ‘male’ half, which are surface mounted to the bottom of the PCB. To connect the glove, microcontrollers etc can then be easily mounted on a separate wrist strap - maybe in an accessible pouch for dev - and connected via standard header pins mounted on the top of the PCB.

ABOVE: glove workshop timelapse

AN OPEN-SOURCE BEND SENSOR GLOVE for VR - prototyping with Artyom Maxim [2017]

TUTORIAL | EXTRA TUTORIAL IMAGES | PROTOTYPING VERSIONS + WORK-IN-PROGRESS CONSTRUCTION IMAGES

1 - 3 - three-fingered configuration with eTextile bend sensors and wired connections [with prototype PCB]

4 - 5 - three-fingered configuration with eTextile bend sensors and conductive textile connections [with prototype PCB]

6 - 8 - finger and thumb ‘pinch’ configuration with eTextile bend sensors and wired connections [+ earlier breadboarded wrist setup]

9 - 10 - finger and thumb ‘pinch’ configuration with eTextile bend sensors and conductive textile connections. Cuff redesigned for extra bend sensor at inner wrist joint.

NIGHT FLOWERS - VICKY BUTTERFLY’S GLOVE CONTROLLER [2015]

VICKYBUTTERFLY.NET - STORY OF THE NIGHT FLOWERS SHOW | CLICK IMAGE TO WATCH →

A delicate [yet incredibly robust!] sheer glove with two switches and wrist-mounted PCB. It enables Vicky Butterfly to control her light cape seamlessly during live performance. The buttons sit on the side of the index finger and palm, controlling on|off and state changes [LED colour/pattern/speed].

The glove design echoes the Bladerunner/Lois Fuller references of Vicky’s amazing costume design. Hidden in the applique are silicone wires which break out a simple commercial battery-powered PCB to the buttons on the glove. The pattern is based on very early MiMU gloves open source patterns developed by Rachel Freire and Hannah Perner-Wilson.

“When the rain falls.. the Night Flowers bloom…” Click the link above to read Vicky’s beautiful origin story of working with light, the movement of fabric… the mysteries of Soho after dark, walking in the rain, and the stories we tell ourselves…

2023 UPDATE [below right] - after 8 years and over 1000 shows [!!!] the glistening lamé is long gone and colour is replaced by a beautiful patina of stitches and thread. How amazing to know it is still in use ♡

ETEXTILE CONTINUITY TESTER - a simple hand mounted switch to make testing circuits more ‘hands-on’ [2014]

DESIGN LANGUAGE - etextile stretch circuits, concept design + dev [2014-21]

TUTORIAL | WORK-IN-PROGRESS IMAGES | SECOND SKIN PROJECT PAGE | SECOND SKIN PAPER TEI2017 [OPEN ACCESS] | SKILLSLEEVES DOCUMENTATION

All the glove designs on this page grew from the development of a design language in the project Second Skin, an exploration of stretch circuits on the body. Using technical knit textiles and mesh with select conductive knits and heat bonding polymers such as Bemis Sewfree stretch adhesives, a whole new world of DIY-able stretchy eTextiles emerges…

A very cool feature of stretch circuits is their ZERO WASTE potential. All the long conductive traces you see here are cut as straight strips, and curves are made when bonding the circuit. Not only are precious [and expensive] silver plated materials used for maximun efficiently, it is great for rapid design and prototyping: you can sculpt and tweak circuits by hand. Additionally, this avoids the waste of materials, time and energy encountered in laser cutting non-stretch fabric into shape.

FOUNDATIONS - MiMU etextile glove explorations, with Hannah Perner-Wilson [2012-2016]

THEGLOVESPROJECT.COM | MEGAGLUVS DEV | MiMU GLOVOLUTION ON PLUSEA.AT | MORE IMAGES ON FLICKR | WWW.MIMUGLOVES.COM

1 - 4: MiMU eTextile prototype [L] and concept design [R] using Eeonyx piezo-resistive and Statex Med-Tex silver plated knits [for sensors and traces, respectively]. Compatible with early MiMU ‘pioneer’ gloves

5 + 10: V.4 MegaGluv using the new MiMU ‘fourchettes’ pattern. MegaGluv uses both plastic Flexpoint bend sensors and eTextile traces, to compare the sensors in real time

6 - 9: textile/pattern dev prototypes [non eTextile] - bonded layers of fine microjersey knit encases sensors, low-profile buttons and LED's within the textile.

11 - 12: initial MegaGluv eTextile prototyping, two different etextile glove designs with embroidered connections

13 - 14: MegaGluv final prototype and testing insulated conductive palm + conductive threads on top. The conductive traces also create the channels for plastic bend sensor placement

15: the first MiMU glove aesthetic design [2012] using custom Flexpoint bend sensors and red vein-like wires, redesigned with sheer technical fabrics to expose the circuitry